NORD-LOCK GROUP EQUIPMENT

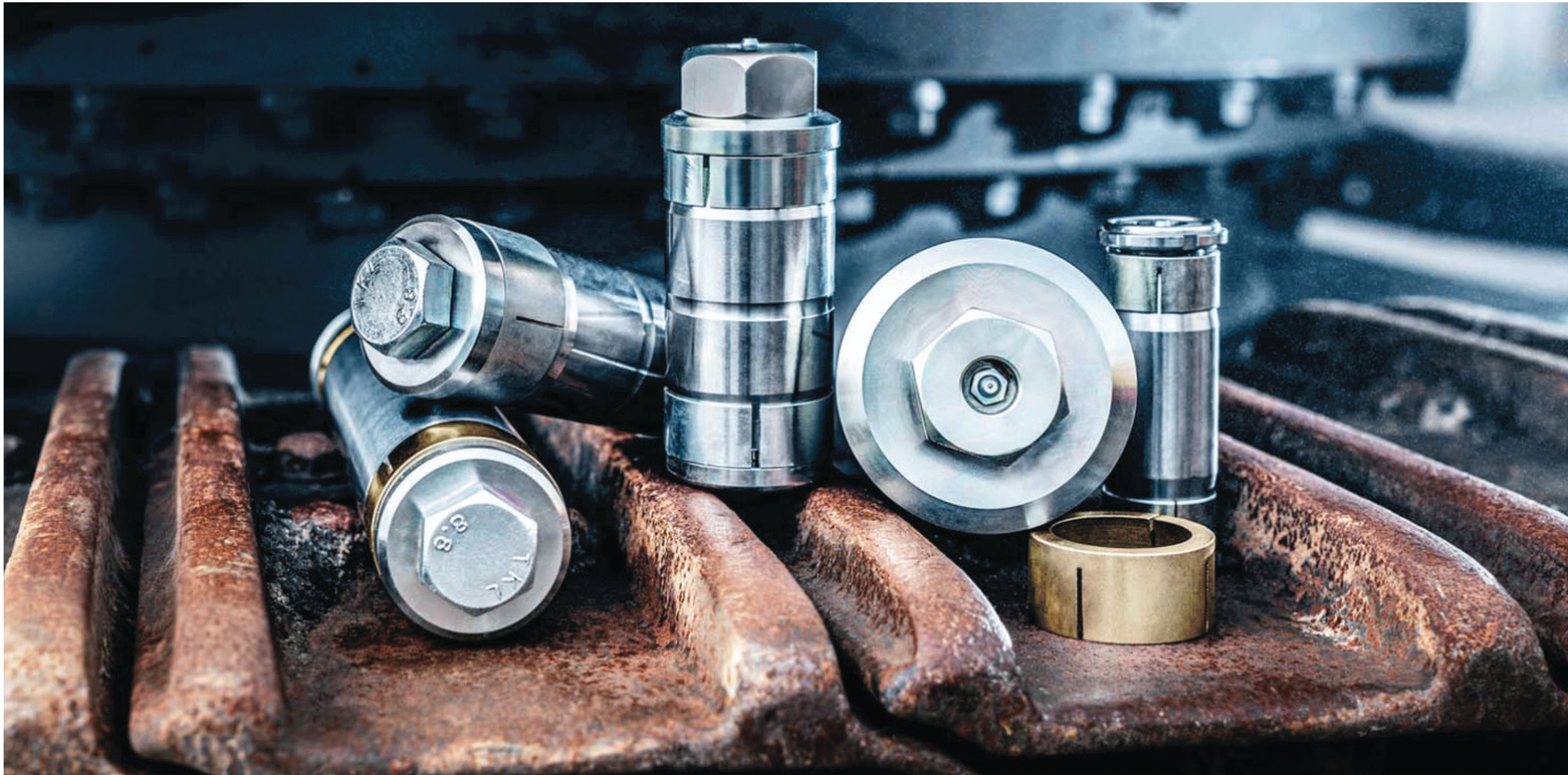

SUPERBOLT TENSIONERS

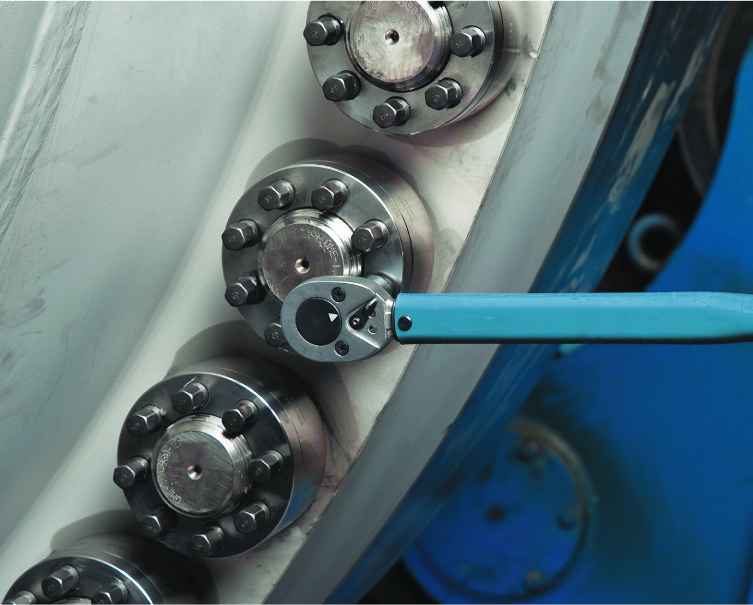

Superbolt tensioners o er you simple and cost-e ective tightening

of large size bolts. Your joints can be tightened with high accuracy without requiring

specialized skills or heavy tooling. A wide range of tensioners is available

in the standard series, as well as an unlimited capacity to create special designs to meet

your unique needs.

SPECS FOR ALL:

- Dimension range: (3/4” – 6”)

- Approx. bolt stress depending on size: 250 to 1200 N/mm2 (35 to 175 ksi)

- Temperature range: -40 to 350ºC (-50 to 650ºF)

ADVANTAGES:

- Quick and easy installation and removal

- Only hand tools required

- Safe method for installation

- Fits in restricted areas

- Pro table life-cycle cost

- Reliable operation

- Simple maintenance procedure

SUPERBOLT FLEXNUTS

Flexnuts have been specially developed for through-hole

applications. Their reactive design distributes the bolt load along many threads, adds

elasticity and prevents stress concentrations in the rst few threads. This helps relieve

stress concentrations and increases the fatigue life of the bolt. Since Flexnuts are

reactive nuts to be used opposite our tensioners, they are never torqued directly to achieve

preload.

SPECS FOR ALL:

- Dimension range: M20 – M160 (3/4” – 6”)

- Approx. bolt stress depending on size: 450 to 900 N/mm2 (60 to 130 ksi)

- Temperature range: -10 to 250ºC (0 to 500ºF)

ADVANTAGES:

- Ensures an equal load distribution on the thread of the bolt/stud, under load

- Adds elasticity in the joint

- Increases the fatigue life of the bolt/stud

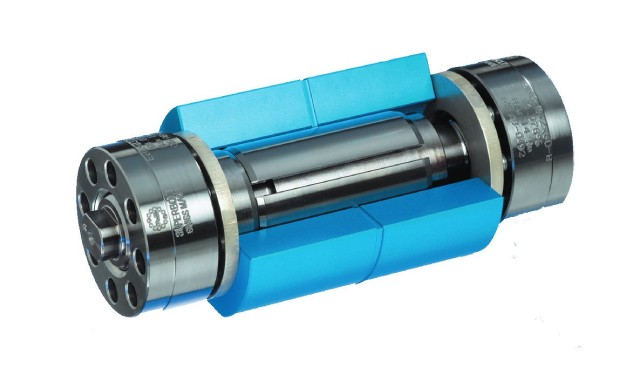

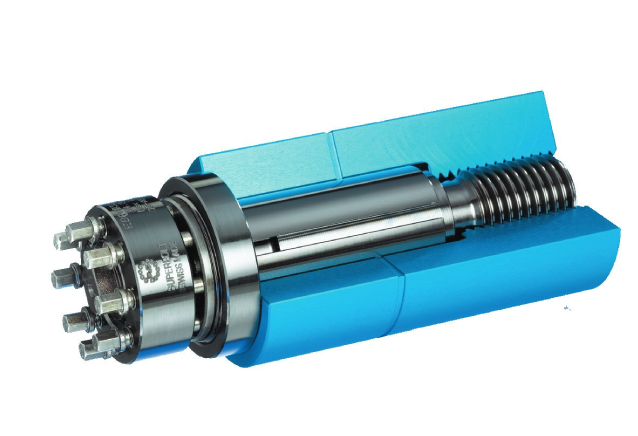

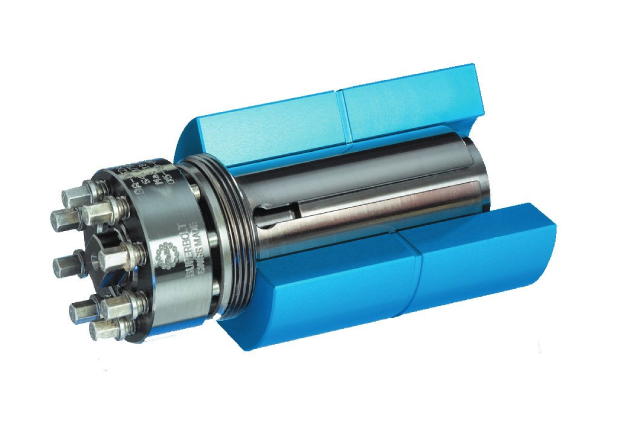

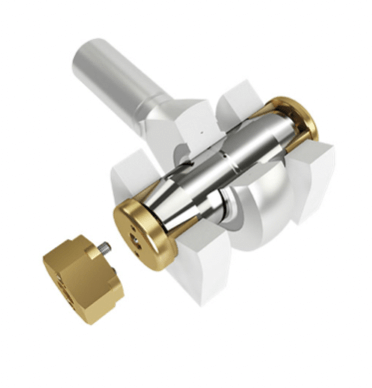

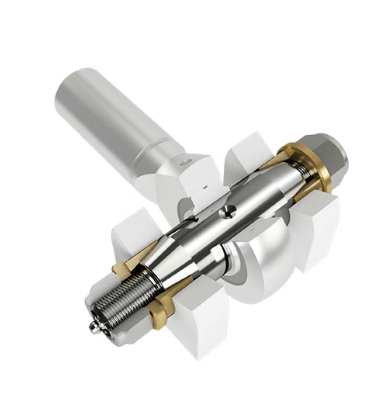

SUPERBOLT EzFit

EzFit mechanical expansion bolts o er tremendous radial expansion

and joint clamping power in one bolting system. They are specially designed for rotating

couplings or alignment systems that require the bolts to transfer forces

in shear.

This innovative product replaces large tted or interference t

bolts, no modi cations required. The key to this solution is the split expansion sleeve that

mates with the customers’ machined holes. The split sleeve requires less

tolerance on mating parts than is traditionally required with interference t, saving

critical machining time.

EzFit mechanical expansion bolts can be designed using latest FEA

technology for any type of coupling with bolts of diameter 20mm (3/4”) or upwards. Unique

features and advantages of both hydraulic and mechanical expansion sleeve

coupling bolts can be combined to best suit your speci c requirements.

SPECS FOR ALL THREE TYPES:

- Mechanical expansion bolt for threadless bore, blind holes, and through-holes

ADVANTAGES:

- Quick and easy to install and remove – only hand tools needed

- No need for special high-powered tools and bolt deep freezing

- Saves money over alternative solutions in time and tooling

- Reusable split sleeve that springs back to original size, use after use

SUPERBOLT LOAD SENSING TENSIONER

Equipped with a strain-measuring device, the patented LST analyzes

the variation of the tensioner’s circumference in proportion to the variation in bolt

preload. Additionally, the LST o ers remote monitoring and a live reading

of data – all with an accuracy that is better than +/-5%!

BENEFITS:

- Remote preload monitoring and a live reading of data

- Facilitates more uptime during service

- Precise and repeatable preload reading

- Eliminates the need for modi cations of the bolt

- Seamless to retro t/upgrade — simply replace original nut with the LST

- Robust and reliable, IP67 classed

- Accurate preload veri cation without adjustment of clamped parts

- No alteration needed of the assembly (including stud or joint design or geometry)

- Removes risk of injuries for operators in hazardous areas

- Eliminates high costs on labor, additional measuring devices and periodic veri cation by

maintenance

TWO OPTIONS:

- LST internal ring (Sensors mounted in the groove):

- CY or MT version

- Standard sizes are M36 – M100

- Standard shaped MJT

- Sensors covered by ring in Delrin material IP67 classed M5 connector in the

nuthouse

TWO OPTIONS:

- LST external ring (Sensors mounted on the outer diameter):

- – Enables the use of more readily available standard conguration multi-jackbolt

tensioners (MJTs) (faster turnarounds can be achieved) - – External protective ring covers the externally mounted sensors and fully

contains the wiring and M5 connector.

- – Enables the use of more readily available standard conguration multi-jackbolt

SUPERBOLT LOAD SENSING FLEXNUT

The LSF’s built-in sensors automatically measure and communicate

preload values, allowing for seamless remote monitoring; and this SMART product can be used

in conjunction with any type of tightening method (tensioning, torquing,

heating, etc.).

BENEFITS:

- Measures preload with an accuracy that is better than ±5%

- Reduces stress concentration of threads

- Easy to operate, no advanced training needed

- Both local and remote monitoring options

- Robust and reliable, IP67 classed

EXPANDER

Lug wear is a common problem with all machinery. Repairs involve a costly, time-consuming process with signi cant downtime and must be repeated several times over a machine’s life.

With the Expander System, the repair can be carried out directly in the worn mountings without welding and line boring – a permanent solution to lug wear.

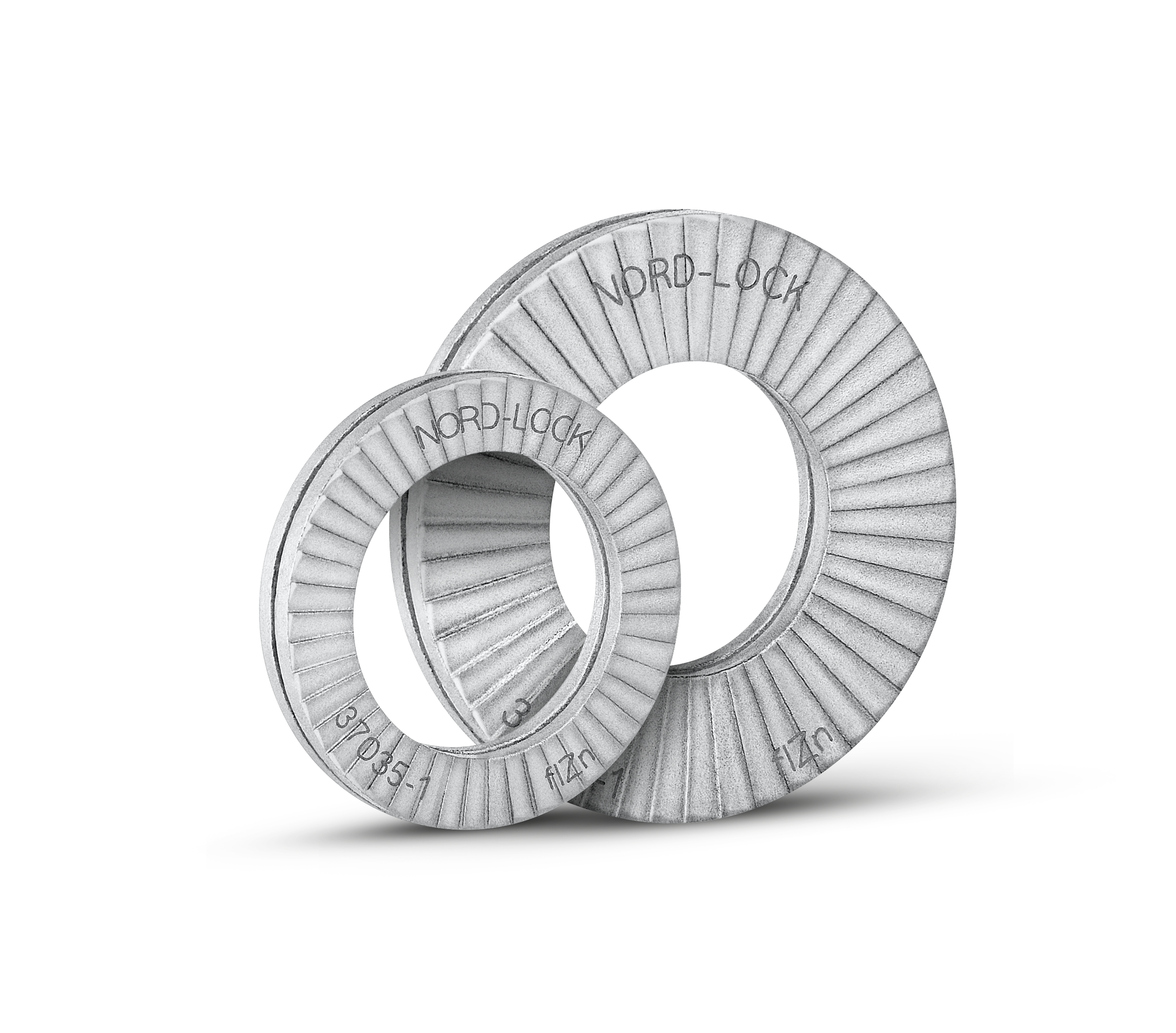

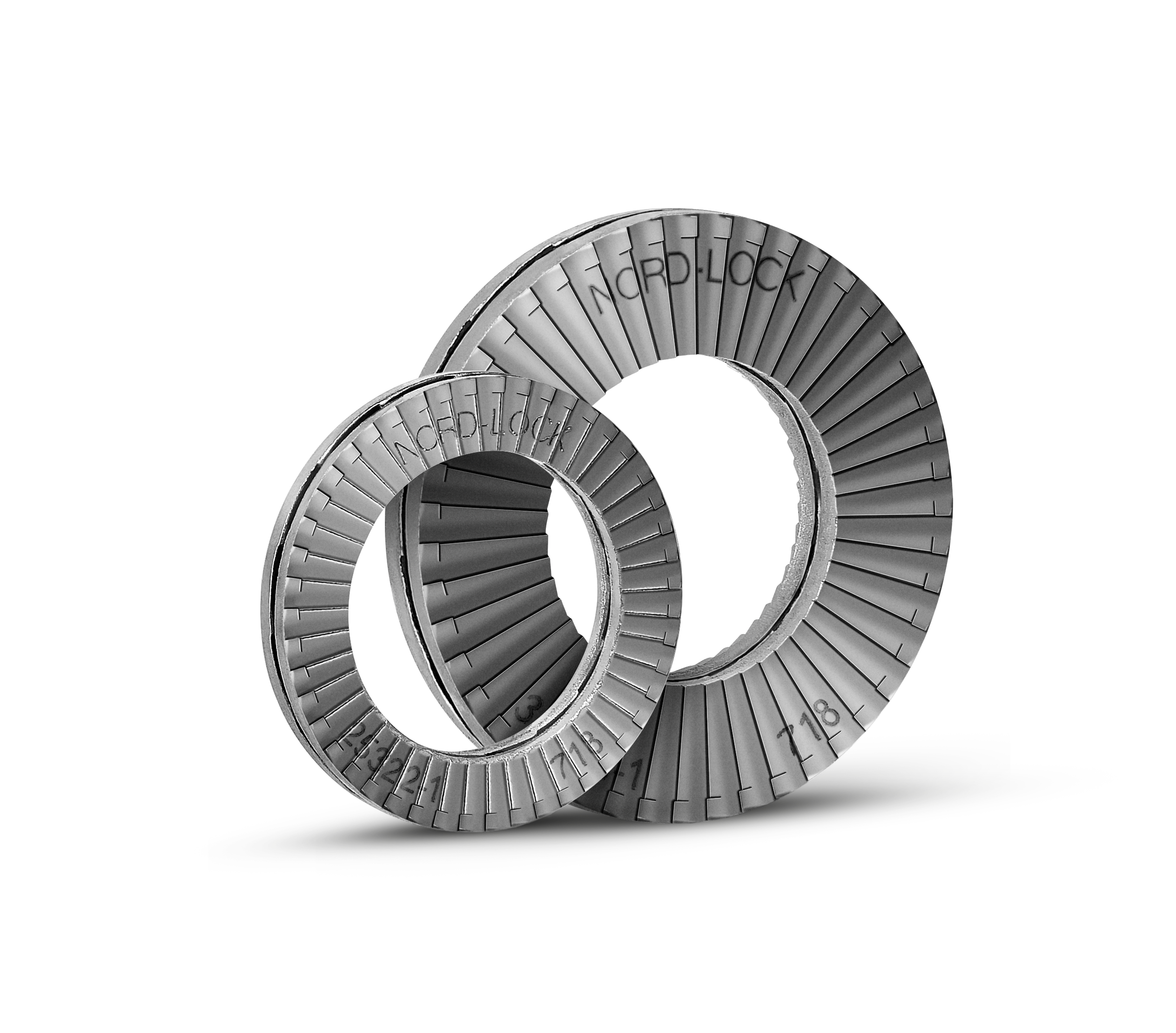

WASHERS

Nord-Lock wedge-locking washers utilize tension instead of

friction in order to secure bolted joints exposed to severe vibration and dynamic loads.

ADVANTAGES:

- Quick and easy to install and remove with hand tools

- Locking function not a ected by lubrication

- High corrosion resistance

- Reliable locking, even for joints with short clamp length

- Reusable (depending on usage environment)

- Reliable operation

- Simple maintenance procedure

Over the operational life cycle, Nord-Lock washers o er increased

operational reliability and accidents and warranty claims. Nord-Lock steel washer promises

the highest corrosion resistance on the market. The washers have been

tested with at least 1,000 hours in the Neutral Salt Spray Test*, ensuring optimum

performance over time, even in the most extreme environments.

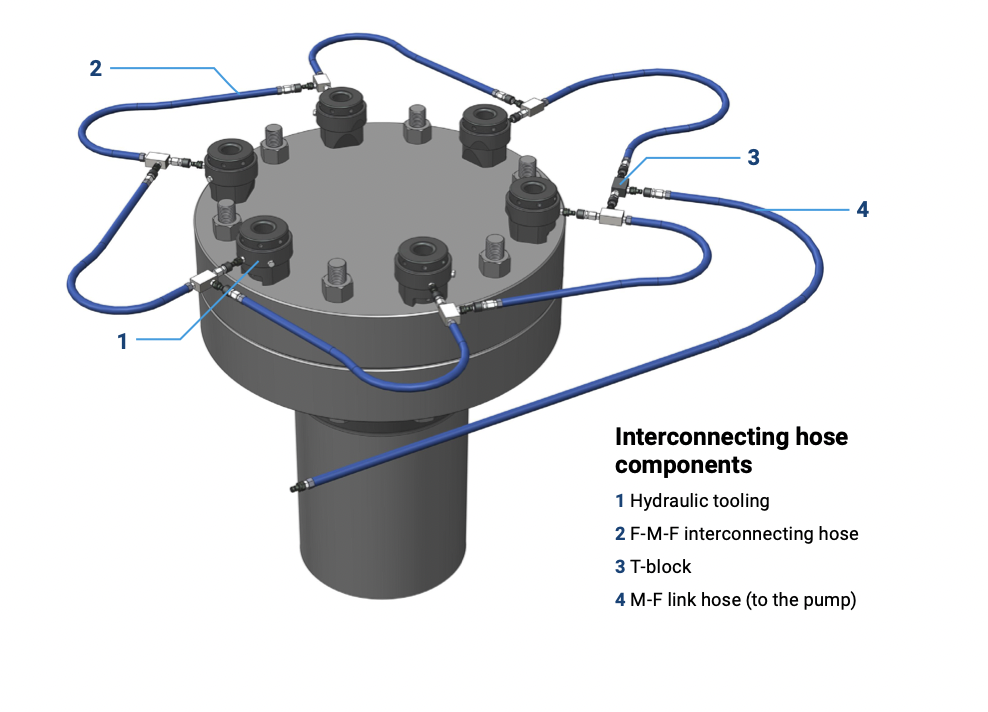

HYDRAULIC NUTS

Hydraulic nuts enable large diameter bolts to be tensioned with

ease to high and accurate preloads. A hydraulic pump activates the internal jacking system,

so the e ort required to tighten a very large diameter bolt is reduced

to the e ort needed to operate the pump.

As there is no nut rotation during tightening, the operation can

be performed in a conned space and torsional stresses on thread damage are eliminated. Any

number of hydraulic nuts can be connected together for simultaneous operation,

ensuring all bolts in the joint can be evenly loaded to the same high and accurate preload.

FEATURES:

- Available as bottom collar, top collar, and shim type

- Standard 1500bar and 2500bar designs

- A20/A15 range

- Substitutes original nut – combines tensioner and permanent nut

- All in one solution – nut remains in place post tensioning

- Special designs available

- Supplied up to M400 in size (to date) – larger sizes quoted

- High temperature solutions available

ADVANTAGES:

- Quick and easy to install

- Even and accurate load as it is developed hydraulically

- No torque or torsion stress

- No ogging hammers or spanners

- Self-aligning (shim)

- Improved fatigue performance

- 100% simultaneous tension

- Long life of internal jack -very compact and cost e ective

- Less stud protrusion required than for tensioners

TWO OPTIONS:

- LST internal ring (Sensors mounted in the groove):

- – CY or MT version

- – Standard sizes are M36 – M100

- – Standard shaped MJT

- – Sensors covered by ring in Delrin material IP67 classed M5 connector in the

nuthouse

TWO OPTIONS:

- LST external ring (Sensors mounted on the outer diameter):