SPECIALTY SERVICES

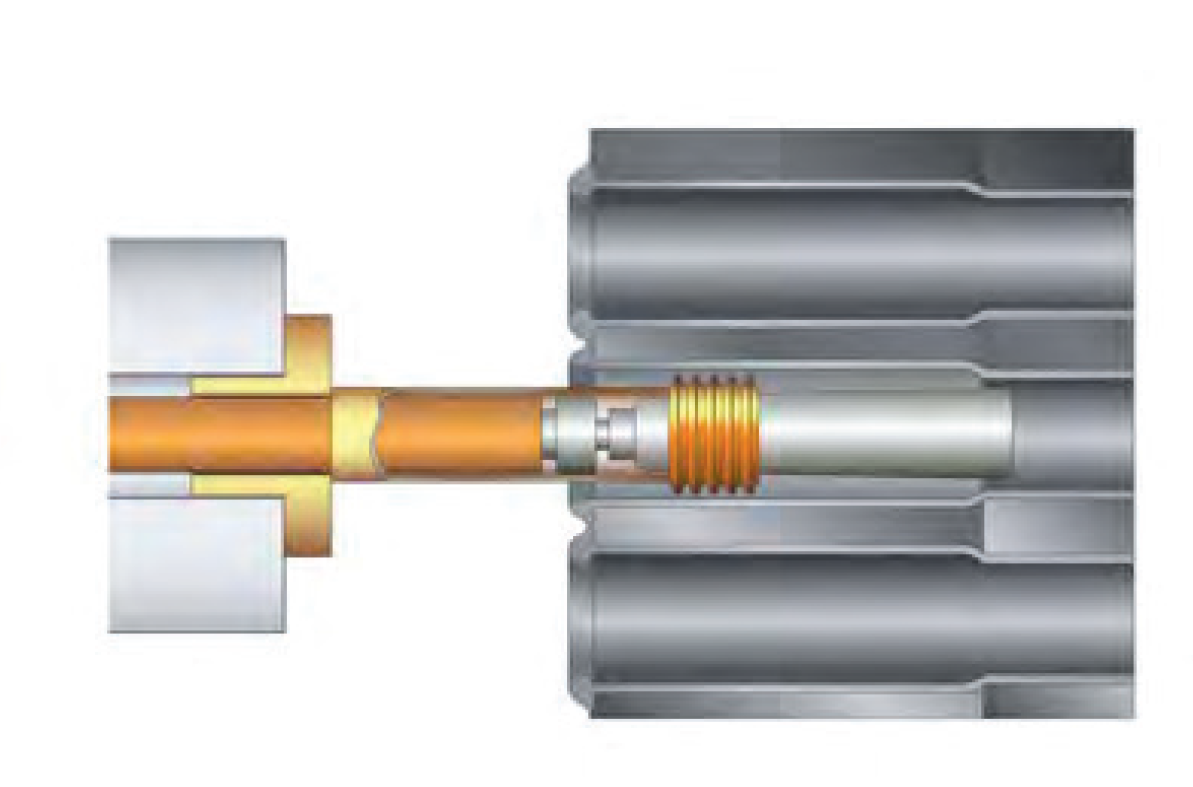

WELD TEST ISOLATION PLUGS

GripTight Test Plugs offer quick, safe, and reliable pressure testing for

open-ended metal pipes and tubing, supporting pressures up to 14,000 PsiG

(960 BarG). They eliminate the need for welding end caps, saving time and money.

The self-gripping design enhances safety by increasing grip with test pressure.

Reusable and featuring a ported shaft for easy system filling, venting, and

draining, they make pressure testing efficient and cost-effective.

Features

- Eliminates welding and cutting end caps

- Self-gripping design increases safety with pressure

- Reusable, reducing test costs by up to 80%

- Sizes range from 0.93″ to 8.53″ (23.6mm to 216.7mm) in stock, with

larger sizes up to 42″ (1066.8mm) available

HEAT EXCHANGER TUBE PLUGS

Our Heat Exchanger Tube Plugs offer a secure solution for tube plugging

without the need for welding or explosives, ensuring maximum uptime with a

helium leak-tight seal and a stable ring/pin design. Rated up to 7,000 PsiG

(483 BarG) and available in sizes from 0.400” to 1.460” (10.16mm to 37.08mm) Tube

I.D., they come in materials such as Brass, Carbon Steel, Stainless Steel,

CuNi, and Titanium.

Features

- Eliminates need for welding or explosives

- Provides Helium leak-tight seal to 1 x 10 – 10 cc/sec

- Metal to metal seal will not leak or degrade like elastomer

plugs - Sizes range from 0.400” to 1.460” (10.16mm to 37.08mm) Tube I.D.

ULTRASONIC TENSION TESTING

Our Ultrasonic Bolt Tension Testing services allow us to provide extremely accurate elongation, stress, and load measurements for fasteners. Utilizing state-of-the-art ultrasonic measuring equipment, this is helpful to identify proper tightening and accurate loads on virtually any bolted connection. It can be accomplished while your facility is up and running or pre/post outage for as-found or as-left benchmarks.

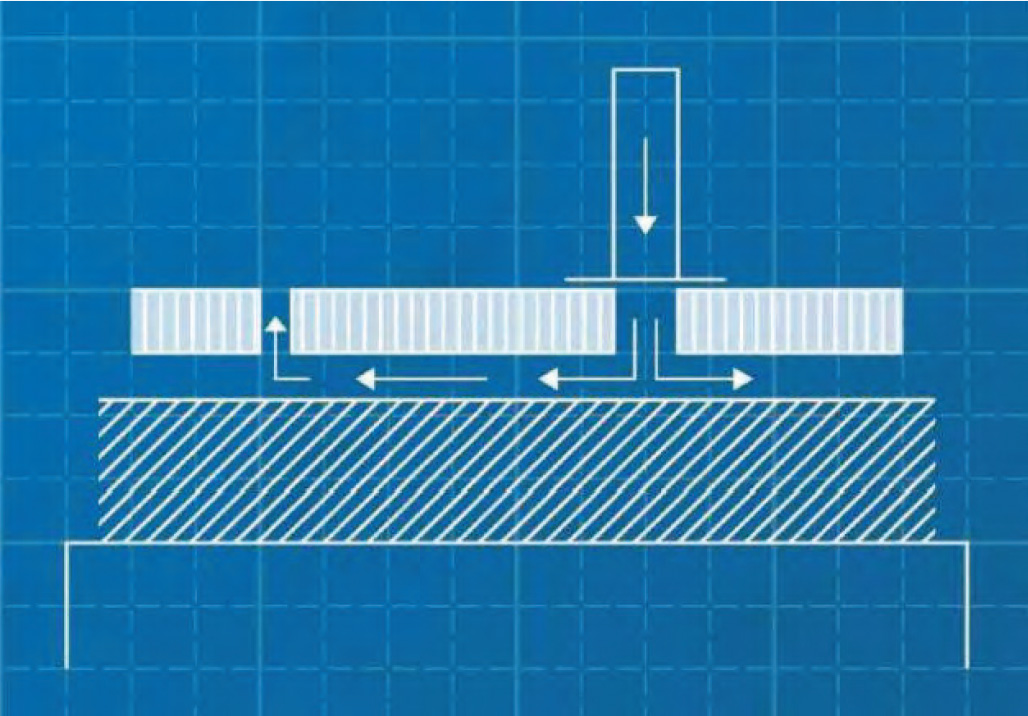

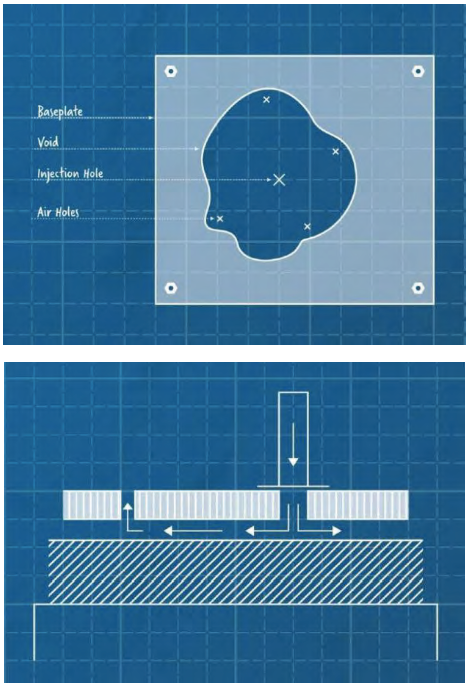

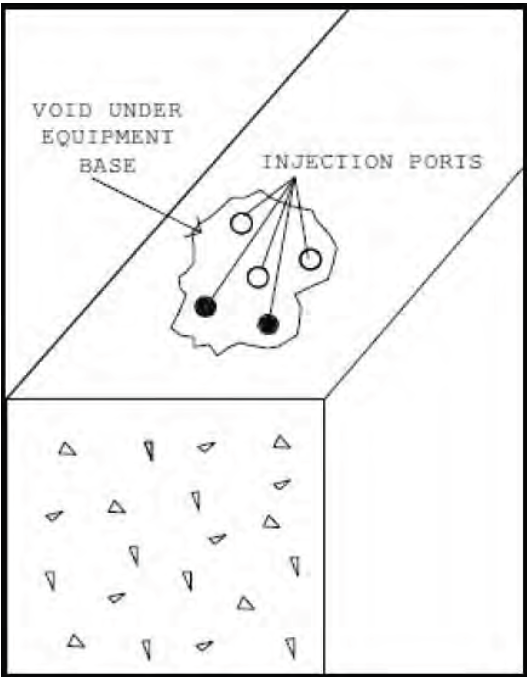

PUMP BASE INJECTION

The filling of grout voids under machine bases with liquid epoxy grouts is a

proven concept that has been used since the late 1960’s. Using injection ports

and vent holes to expel trapped air, a liquid “shim” of epoxy grout, as strong

as the grout below it, is pumped or gravity fed into the void. Upon curing, the

liquid epoxy becomes hard and fills the cavity, providing support at machine

pedestals and can reduce vibration in adjacent plate sections.

Features

- Reduce vibration and premature degradation of concrete pump bases

- Drill and inject two-part epoxy to fill voids and reinforce the base

- Can also apply a perimeter seal to contain epoxy if the base is

verydeteriorated