FIELD MACHINING SERVICES

Millennium Industrial Services provides the highest quality field machining services available with our experienced technicians and the state of the art equipment. Our safe, efficient field machining services will help you meet your deadlines in budget.

PIPE CUTTING & BEVELING:

- Internal mount and external mount equipment- for the cutting of thin or thick wall pipes

- Equipment is lightweight with low radial and axial clearances for weld

preparation,

valve fittings, and related components - Ideal for pipe maintenance and construction work in nuclear and fossil power plants, pipelines, oil platforms, petrochemical plants, and refineries, as well as shipbuilding, pharmaceutical, food, beverage, and other high purity piping applications

- Can cut, bevel, and counter bore pipe from 2” through 120” O.D. on all schedules and alloys

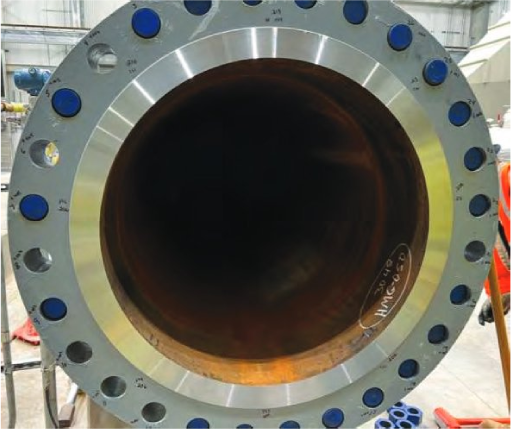

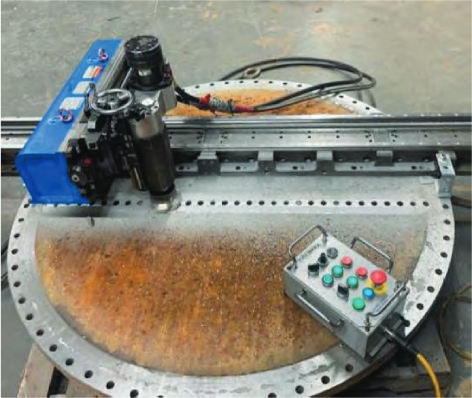

FLANGE FACING

- PMIS can machine virtually any size and type of flange from Raised Face to Ring

Joints - Utilize both O.D. Mount and I.D. Mount Equipment

- No matter the flange, we can machine it in place and all work is done to industry

standards and specifications - Our equipment is durable, easy to maneuver, and capable of handling your fiange

facing needs at peak industry standards

PORTABLE MILLING

- MIS offers a variety of milling services for many applications including

motorbases

and other rotating equipment as well as plates, presses, roughing and finishing

mill tracks, etc - Equipment is capable of both large surface area machining as well as fitting in

very tight quarters - Capabilities include custom modifications and setups

- Offer various sizes and configurations with extensive fixtures and capacity

- MIS can handle pressures up to the rating of the pipe

- Milling machines perform a vast number of operations, such as slot cutting,

planing, drilling, die-sinking, rebating, routing, etc.

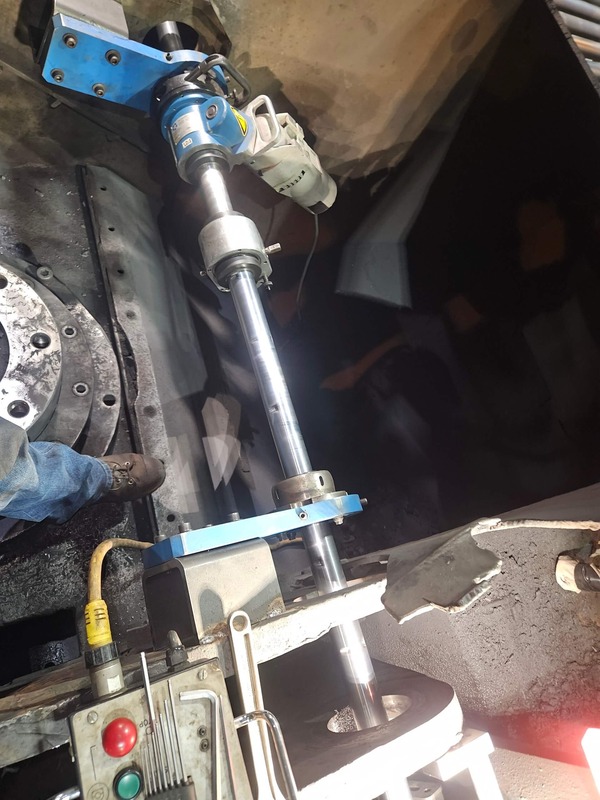

LINE BORING

We have the capability to line bore and reface equipment in the field from 1-3/4” to 96” diameters and up to 24’ in length.

STUD REMOVAL SERVICES

Our core drilling process is guaranteed to save you time and money. Instead of drilling

the studs in several stages, we will core the stud to within 1/32” of the minor diameter

in only one step with only one bit! Conventional drilling requires multiple stages, more

man hours, and more consumables. Our core drilling method can reduce drilling time from

3 to 8 hours per stud just 10 to 30 minutes per stud!

- 11/16” to 5-3/8” Diameter

- Up to 12” Deep

- Core Drilling

- Twist Drilling